Piston pumps operate on the fundamental principle of positive displacement.

A piston inside a cylinder moves back and forth to displace a fixed volume of fluid with each stroke. As the piston moves away from the inlet, it creates a low-pressure area that allows the fluid to enter the cylinder. When the piston moves back towards the inlet, it compresses the fluid, increasing its pressure and forcing it out through the outlet.

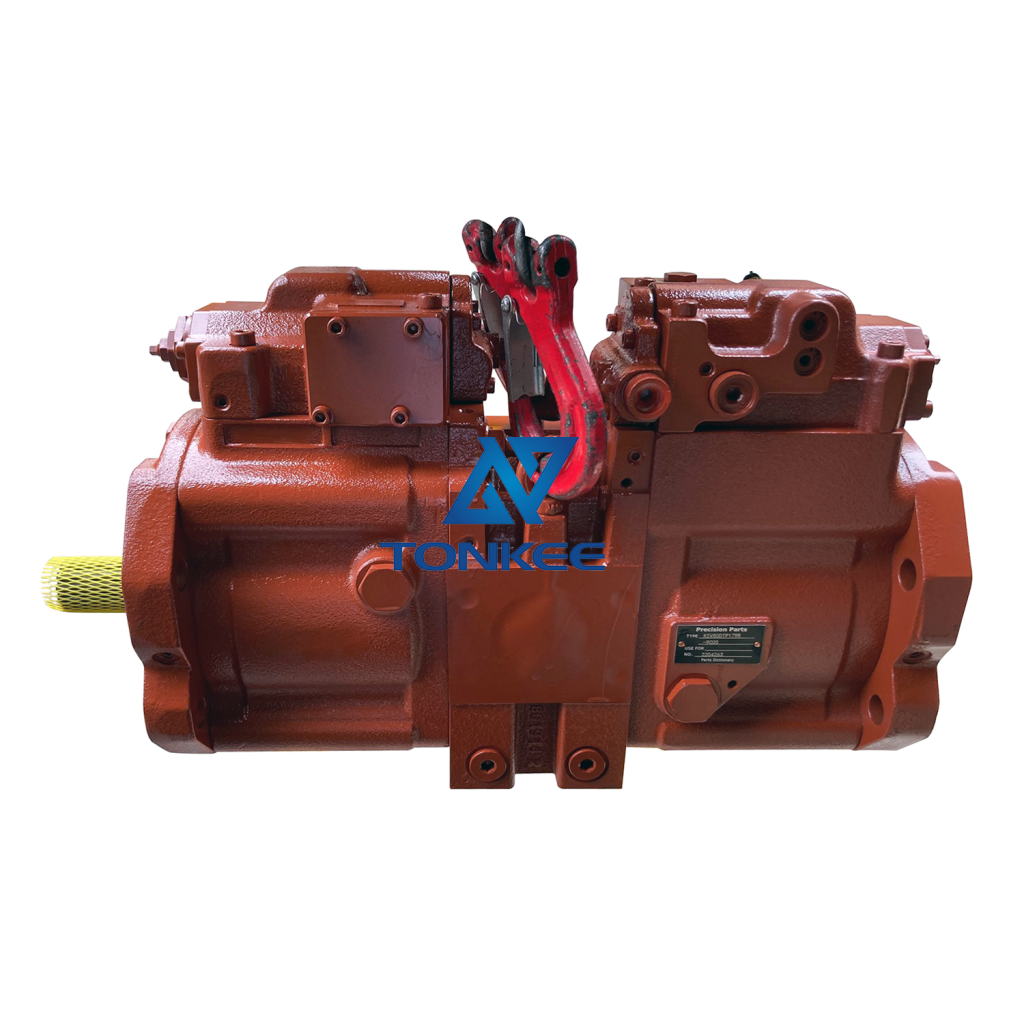

Components:

Cylinder: The cylinder is the housing for the piston and serves as the chamber in which fluid is displaced.

Piston: The piston is a key component that moves inside the cylinder. It is typically sealed with rings to prevent leakage.

Inlet and Outlet Ports: These ports allow the fluid to enter and exit the cylinder. Valves are often used to control the flow direction.

Drive Mechanism: Piston pumps can be powered by various means, including electric motors, internal combustion engines, and manual operation.

Valves: Check valves are often used to ensure one-way flow in and out of the cylinder.

Specifications:

Flow Rate: The flow rate of a piston pump typically ranges from a few liters per minute to thousands of liters per minute, depending on its size and design. High flow rates are suitable for applications where large volumes of fluid need to be moved.

Pressure Rating: Piston pumps can generate high pressures, often exceeding 10,000 psi (689 bar). The pressure rating varies based on the design and materials used.

Materials: Piston pumps can be constructed from a variety of materials, including stainless steel, cast iron, and various alloys. Material selection is crucial to ensure compatibility with the fluid being pumped.

Sealing Mechanism: Piston pumps use seals or piston rings to prevent leakage of fluid.

The type of seal and its quality are important factors in a pump's performance and longevity.

Drive Type: Piston pumps can be powered by electric motors, gasoline or diesel engines, pneumatic systems, or manual operation. The drive type should be selected based on the specific application and power source available.

Applications:

Piston pumps are versatile and find use in a wide range of applications:

Hydraulic Systems: They are commonly used in hydraulic systems for heavy machinery, construction equipment, and manufacturing.

Oil and Gas Industry: Piston pumps are employed for high-pressure oil and gas transfer, as well as for drilling and well-servicing operations.

Chemical Processing: They are used for precise dosing and transferring of chemicals in industrial processes.

Water Jet Cutting: High-pressure piston pumps are used in water jet cutting machines to slice through various materials.

English

English Русский язык

Русский язык