Displacement Range: The PVD-2B Series offers a displacement range from 16 cc/rev to 236 cc/rev.

This versatility allows the pump to cater to various flow rate requirements.

Pressure Rating: The series can handle pressures up to 315 bar (4568 psi). This high-pressure capability makes it suitable for demanding hydraulic systems.

Speed Range: The pump's speed range can vary from 600 to 2700 RPM, providing flexibility for different operational needs.

Temperature Range: It can operate within a temperature range of -20°C to 80°C (-4°F to 176°F), making it suitable for diverse environmental conditions.

Fluid Compatibility: The PVD-2B Series is compatible with a wide range of hydraulic fluids, including mineral oil-based fluids and certain synthetic fluids.

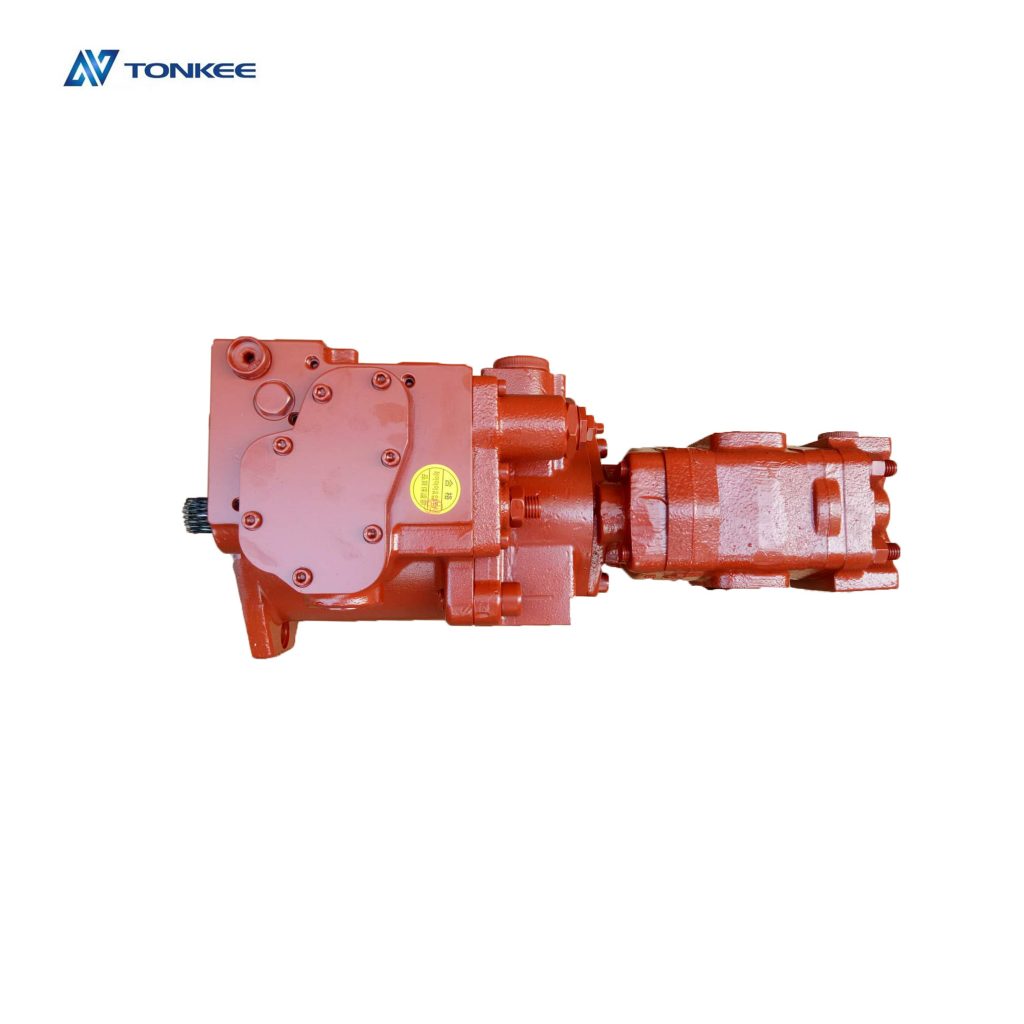

Parts and Components:

The PVD-2B Series Piston Pump consists of several critical parts and components, each playing a unique role in ensuring its efficient and reliable operation:

Cylinder Block: The cylinder block houses multiple pistons that reciprocate to generate fluid flow. This component's design and quality are critical for maintaining consistent performance.

Pistons: Pistons are responsible for generating the hydraulic force within the pump.

They move within the cylinder block to displace fluid and create pressure.

Valve Plate: The valve plate is an essential component for controlling the flow of hydraulic fluid within the pump. It includes various valves that regulate fluid flow and pressure.

Swash Plate: The swash plate is an adjustable component that controls the angle of the pistons in the cylinder block. By altering the angle, the pump can vary its displacement and flow rate.

Control Mechanism: PVD-2B Series pumps are equipped with various control mechanisms, including servo controls, to precisely manage the displacement and pressure output.

Shaft and Bearings: The shaft connects the pump to the power source, and high-quality bearings are crucial for reducing friction and ensuring smooth operation.

Ports and Connectors: The pump has inlet and outlet ports for hydraulic fluid connections, along with additional ports for control and feedback devices.

Housing and Seals: The housing provides structural support and protection for the internal components. Seals are used to prevent hydraulic fluid leakage and maintain the pump's integrity.

English

English Русский язык

Русский язык