Working Principle: Piston pumps work on the principle of reciprocating motion.

A piston inside a cylinder moves back and forth to displace and transfer the fluid.

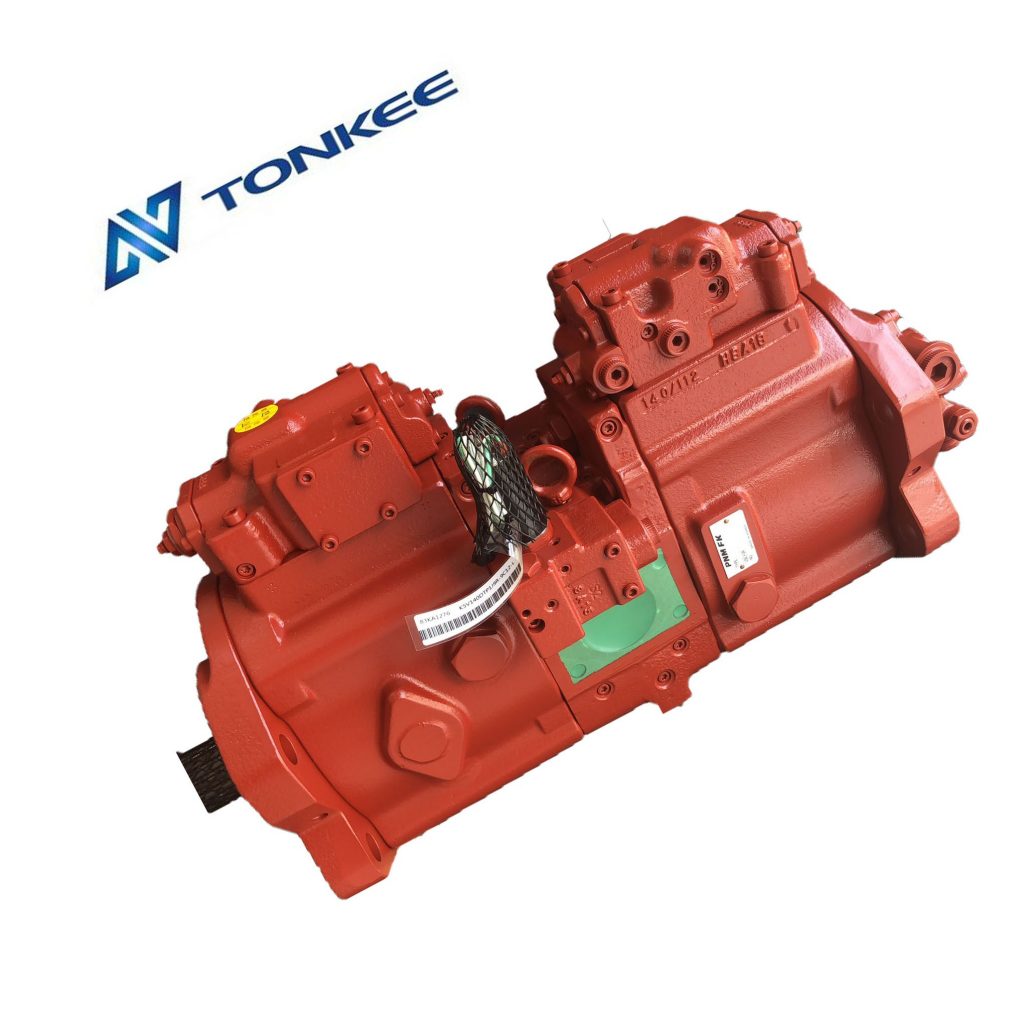

Types: There are two primary types of piston pumps: axial piston pumps and radial piston pumps. Axial piston pumps have pistons that move parallel to the pump shaft, while radial piston pumps have pistons that move radially outward from the center.

Flow Rate: The flow rate of a piston pump can vary widely depending on the specific model and application. They are capable of providing both low and high flow rates, making them versatile for various tasks.

Pressure Rating: Piston pumps are known for their ability to generate high pressures, typically in the range of 1,000 to 10,000 psi (pounds per square inch) or more. The pressure capability depends on the design and construction of the pump.

Materials of Construction: Piston pumps are often made from durable materials such as stainless steel, cast iron, or various alloys to withstand the demands of different applications and the fluids being pumped.

Seals and Gaskets: High-quality seals and gaskets are essential in piston pumps to prevent fluid leakage and maintain efficiency.

They are usually made of materials that can withstand high pressures and a wide range of temperatures.

Control Mechanisms: Many piston pumps offer precise control mechanisms, including variable displacement, which allows the operator to adjust the flow rate and pressure according to the specific requirements of the task.

Power Source: Piston pumps can be powered by electric motors, internal combustion engines, or even hydraulic systems, depending on the application.

Maintenance: Regular maintenance is crucial to ensure the longevity and reliability of piston pumps. Maintenance tasks may include inspecting and replacing seals, gaskets, and other wear parts.

English

English Русский язык

Русский язык