Piston pumps are categorized as positive displacement pumps, meaning they displace a fixed amount of fluid per cycle.

In a piston pump, a piston moves back and forth within a cylinder, creating alternating low and high pressure to draw in and expel the fluid.

Types of Piston Pumps:

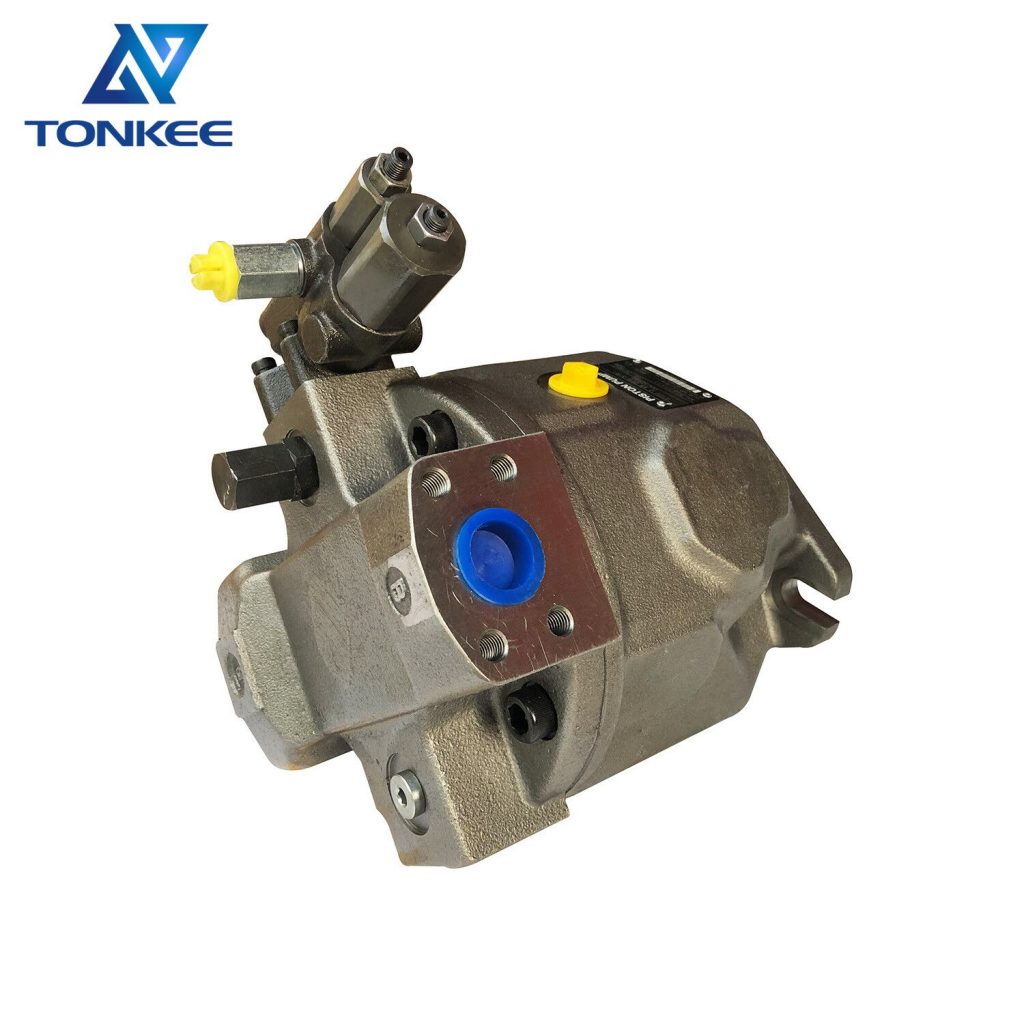

There are various types of piston pumps, including axial piston pumps and radial piston pumps. Axial piston pumps have pistons arranged parallel to the drive shaft, while radial piston pumps have pistons arranged in a radial pattern around the drive shaft.

A typical piston pump consists of a cylinder, a piston, intake and discharge valves, and a drive mechanism. The cylinder houses the piston, which is connected to the drive mechanism. Intake valves allow fluid to enter the cylinder during the suction stroke, while discharge valves permit fluid to exit during the discharge stroke.

Flow Rate and Pressure:

The specifications of a piston pump include its flow rate and pressure capacity. Flow rate is typically measured in gallons per minute (GPM) or liters per minute (LPM), while pressure is measured in pounds per square inch (PSI) or bar. The specific values depend on the design and intended application of the pump.

Fluid Compatibility:

Piston pumps are used for a wide range of fluids, including water, oil, chemicals, and more. It's crucial to ensure that the pump materials and design are compatible with the specific fluid being handled to prevent corrosion or damage.

Efficiency and Energy Consumption:

Piston pumps are known for their high efficiency, which is important for minimizing energy consumption.

Efficiency is a measure of how well the pump converts mechanical energy into hydraulic energy. High-efficiency piston pumps are ideal for applications where energy conservation is a priority.

Controllability:

Piston pumps can often be controlled to modulate flow rates and pressures as needed. This controllability is valuable in various applications, such as hydraulic systems in heavy machinery, where precise control is required.

Maintenance and Serviceability:

Regular maintenance is essential to ensure the long-term performance of a piston pump. The design should facilitate ease of maintenance, including access to critical components for inspection, cleaning, and repair.

Noise and Vibration:

Piston pumps can generate noise and vibrations during operation. Noise levels and vibration characteristics should be considered, especially in applications where noise pollution and smooth operation are significant concerns.

Environmental Considerations:

Piston pumps must comply with environmental regulations and safety standards. This may involve features like leak detection, seal integrity, and materials that are safe for use with specific fluids.

English

English Русский язык

Русский язык