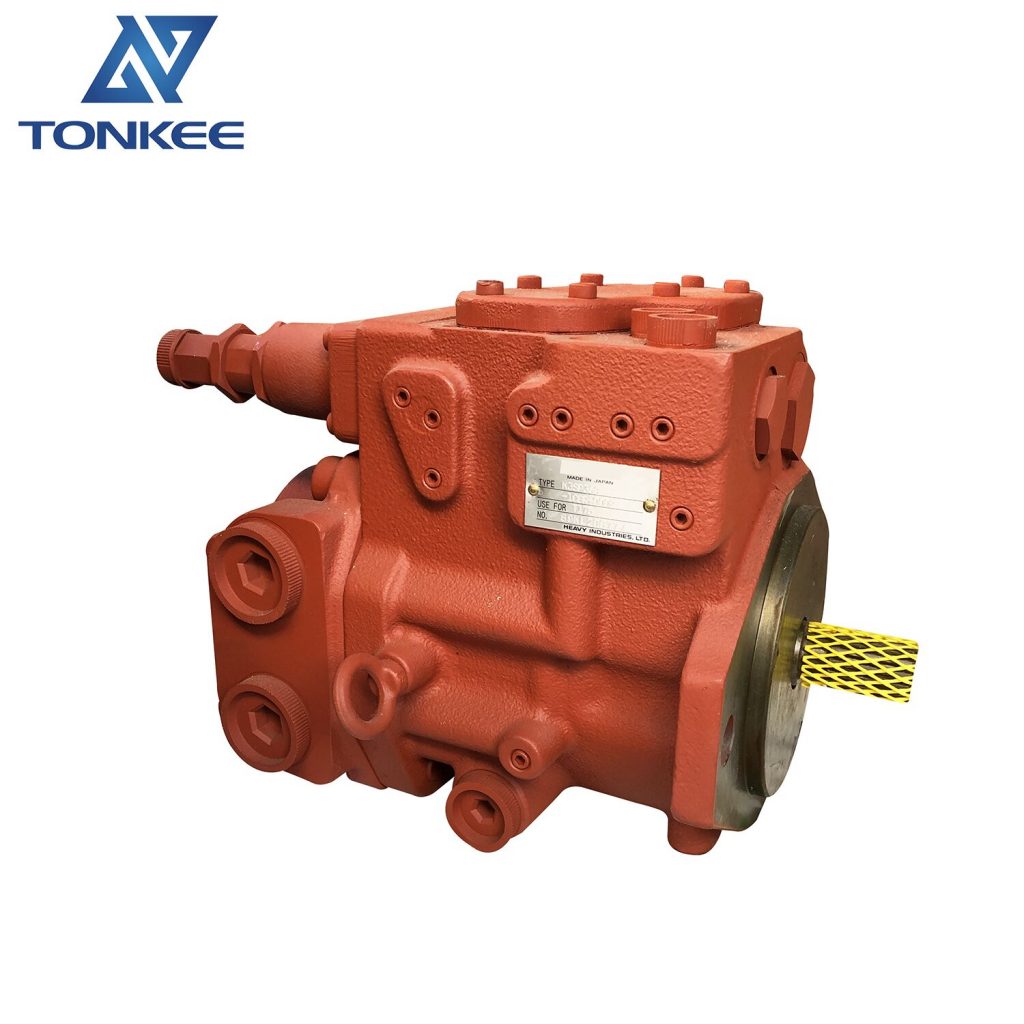

The Bell B210835 Hydraulic Charge Pilot Pump 74318DDA Gear Oil Pump is designed for use in hydraulic systems, particularly those requiring the precise control and distribution of hydraulic fluids.

It is also suitable for lubricating gear systems and other machinery components requiring oil circulation and pressure control.

Construction:

This gear oil pump is constructed with high-quality materials to ensure durability and reliability. The housing is typically made from robust materials such as cast iron or steel, which can withstand the rigors of industrial applications. The internal gears, which are responsible for fluid displacement, are typically made from hardened steel or other wear-resistant materials.

Operating Principle:

The 74318DDA Gear Oil Pump operates on the principle of positive displacement. It consists of two meshing gears that trap and move fluid between the teeth as they rotate. This design provides a constant and consistent flow of hydraulic or gear oil.

Flow Rate and Pressure Rating:

The specific flow rate and pressure rating of the Bell B210835 Hydraulic Charge Pilot Pump can vary depending on the model and application requirements. These pumps are available in various sizes and specifications, and the performance characteristics can be tailored to suit different needs. Flow rates can range from a few liters per minute to several hundred liters per minute, while pressure ratings can vary from a few bar to several hundred bar.

Mounting Options:

This gear oil pump can be mounted in various orientations, making it versatile for different installation needs.

Common mounting options include flange, foot, and vertical mounting.

Drive Mechanism:

The Bell B210835 Hydraulic Charge Pilot Pump can be driven by various means, including electric motors, internal combustion engines, and power take-offs (PTOs) from other machinery. The choice of drive mechanism depends on the specific application and the availability of power sources.

Sealing and Lubrication:

To prevent leakage and ensure long-lasting performance, these pumps are equipped with robust sealing systems. Common seals include lip seals, mechanical seals, or O-rings, depending on the pump's design and application. Lubrication of the internal components is typically achieved through the hydraulic or gear oil being pumped, which helps reduce wear and maintain efficiency.

Temperature Range:

The Bell B210835 Hydraulic Charge Pilot Pump is designed to operate within a specified temperature range, which varies depending on the model and materials used. Some pumps can handle extreme temperatures, making them suitable for both cold and hot environments.

Noise and Vibration Control:

Efforts are made to minimize noise and vibration during operation. This can include design features such as helical or herringbone gears to reduce noise and improve smooth operation.

English

English Русский язык

Русский язык