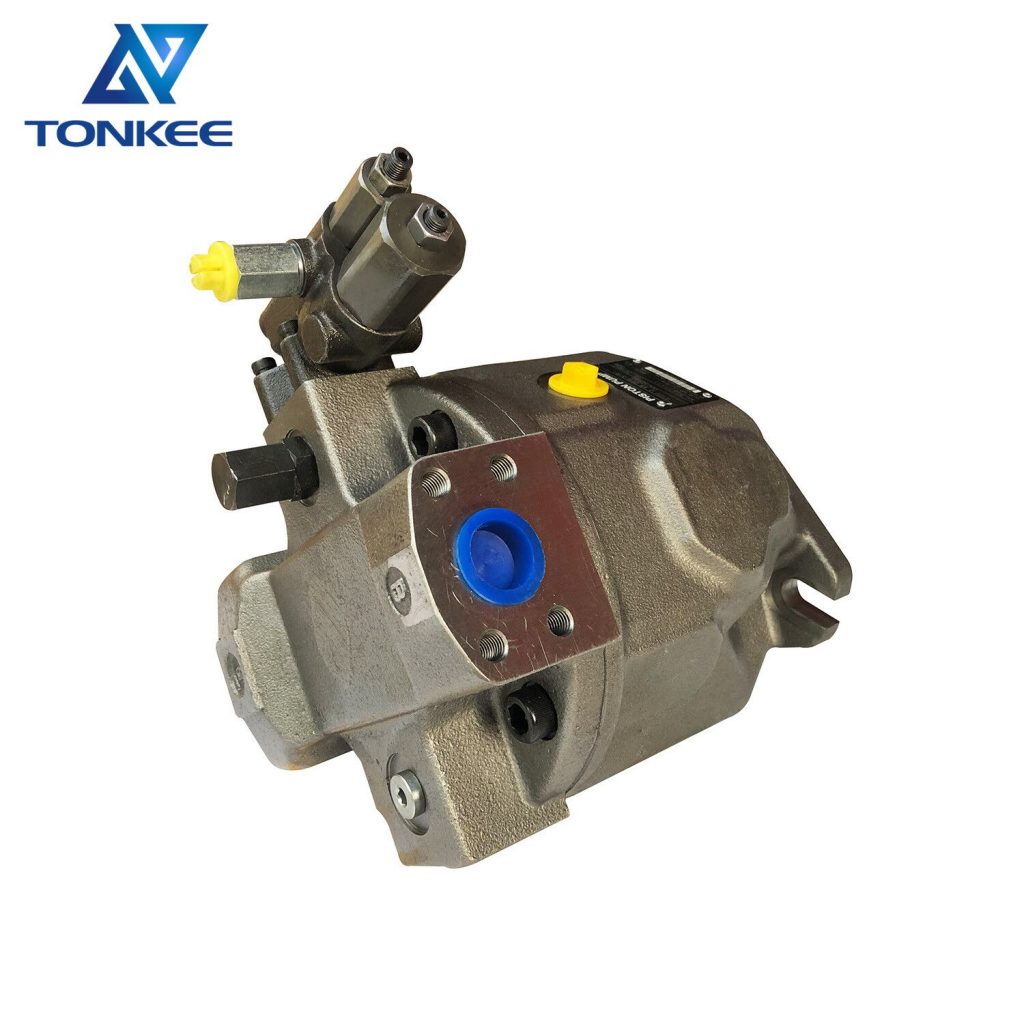

The HPR Series Piston Pump is known for its robust design and high efficiency.

It is a positive displacement pump, which means that it moves a fixed amount of fluid with each stroke or cycle. The key components include pistons, cylinders, a swashplate, and a housing.

Pressure Rating:

The HPR Series Piston Pump is capable of generating extremely high pressures, typically in the range of 3000 to 5000 PSI (pounds per square inch). This makes it suitable for applications requiring substantial hydraulic force.

Flow Rate:

These pumps are designed to provide a specific flow rate, usually measured in liters per minute (LPM) or gallons per minute (GPM). The flow rate can vary depending on the model and specifications.

Piston Arrangement:

HPR Series Piston Pumps come in various piston arrangements, such as axial piston pumps and radial piston pumps. Axial piston pumps are known for their high efficiency and are commonly used in mobile hydraulic systems, while radial piston pumps are often used in industrial applications.

Variable or Fixed Displacement:

HPR Series Piston Pumps can be variable or fixed displacement. Variable displacement pumps allow for control of the fluid flow, which is essential in applications where varying output is needed. Fixed displacement pumps provide a constant flow rate and are suitable for applications with a consistent demand.

Swashplate Mechanism:

A swashplate is a critical component in axial piston pumps. It allows for the conversion of rotary motion into linear motion.

By adjusting the angle of the swashplate, the displacement of the pump can be controlled, enabling variable flow rates.

Cylinder Block:

The cylinder block houses the pistons, and it is a key part of the pump. The number and arrangement of cylinders within the block depend on the specific model. It is made from high-strength materials to withstand the high pressures and forces generated during operation.

Control Mechanisms:

Many HPR Series Piston Pumps come with control mechanisms such as pressure compensators, load-sensing control, and flow controls. These features allow for precise control and adjustment of the pump's output to match the requirements of the hydraulic system.

Materials and Durability:

These pumps are typically constructed from high-quality materials, such as hardened steel, to ensure durability and resistance to wear and tear. This is essential for their reliable operation in demanding industrial environments.

Mounting Options:

HPR Series Piston Pumps are designed to be easily mounted within hydraulic systems, offering various options for installation and connection to other components, such as hydraulic motors and actuators.

Maintenance and Serviceability:

Regular maintenance is essential to ensure the long-term reliability of HPR Series Piston Pumps. They may require periodic inspection, seal replacement, and fluid changes to maintain optimal performance.

English

English Русский язык

Русский язык